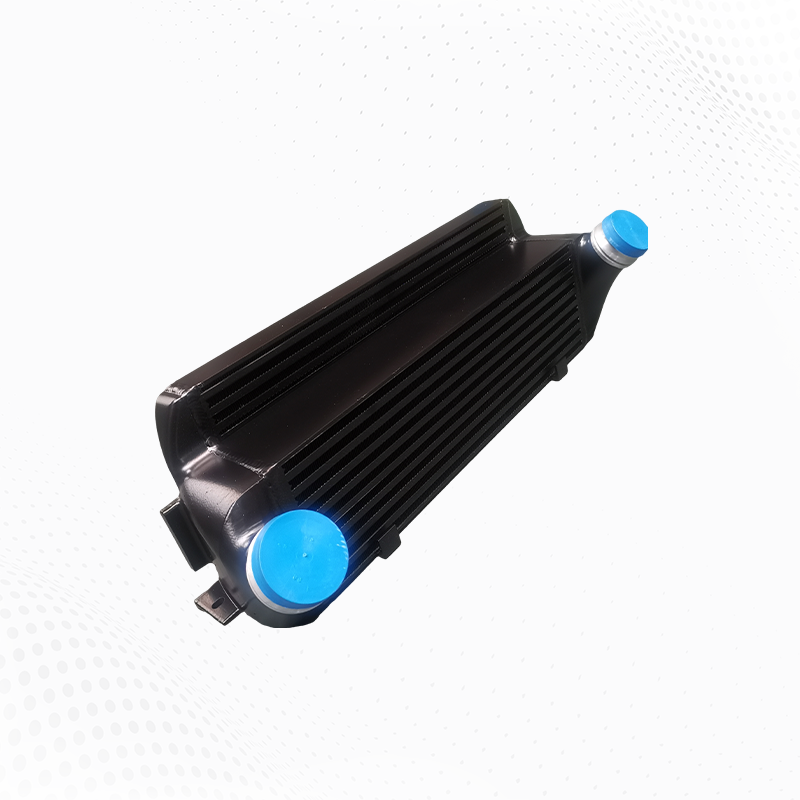

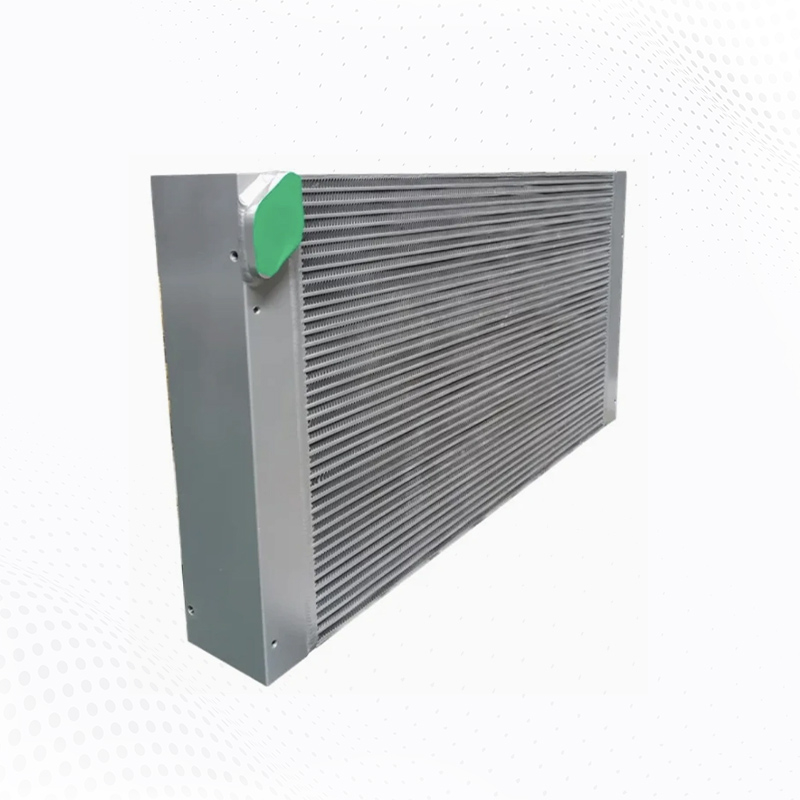

Hydraulic Cooler

A hydraulic cooler is a vital component in any hydraulic system. Its primary function is to regulate the temperature of the hydraulic fluid, ensuring it remains within an optimal range for system performance. Overheating of hydraulic fluid can lead to a variety of problems, including reduced viscosity, accelerated wear of components, and system failure. The hydraulic cooler helps prevent these issues by removing excess heat from the fluid, allowing the system to run smoothly and efficiently.

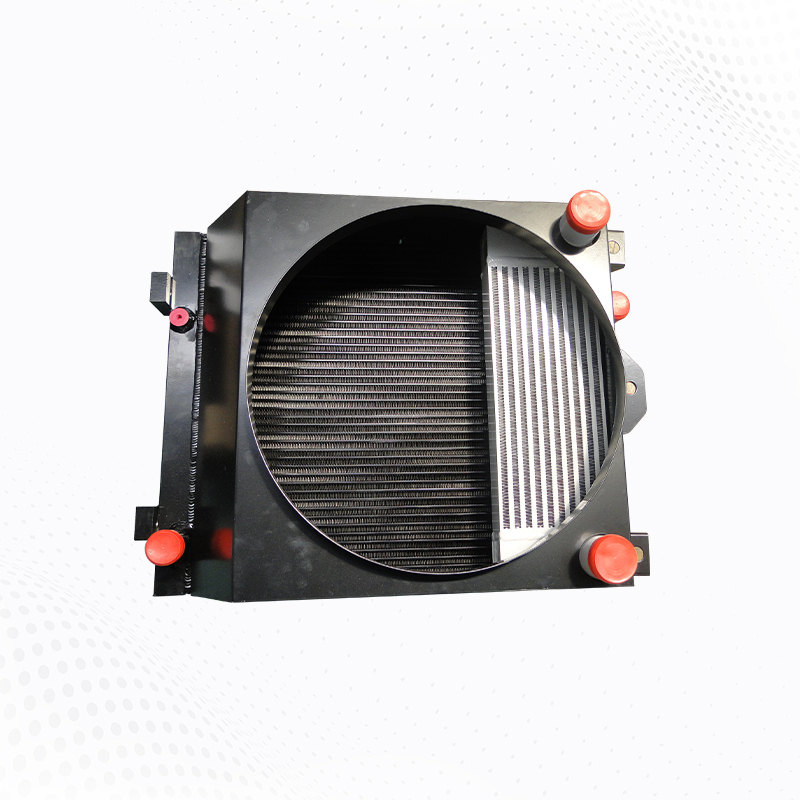

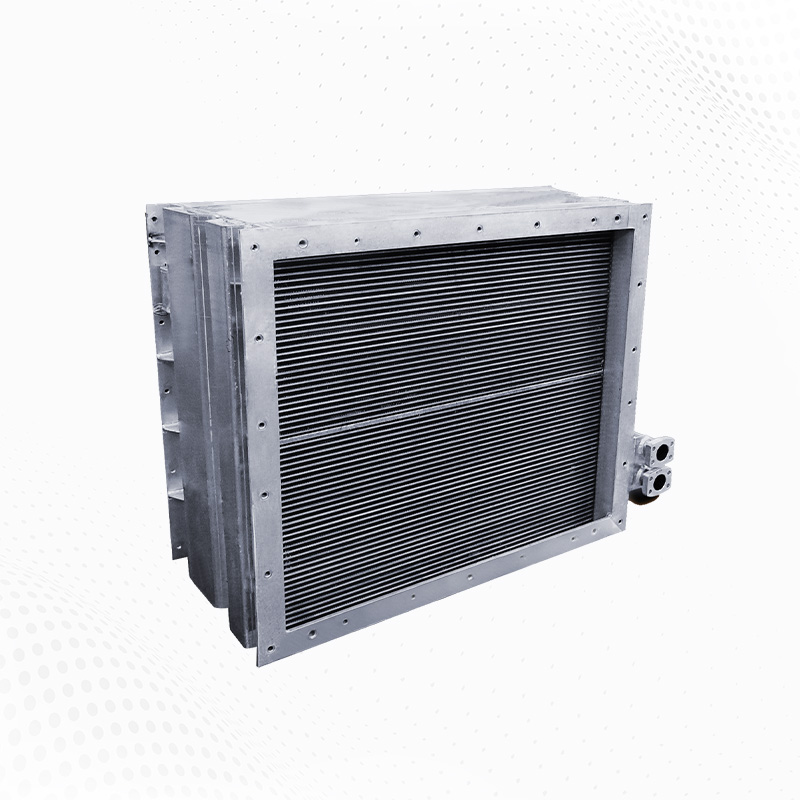

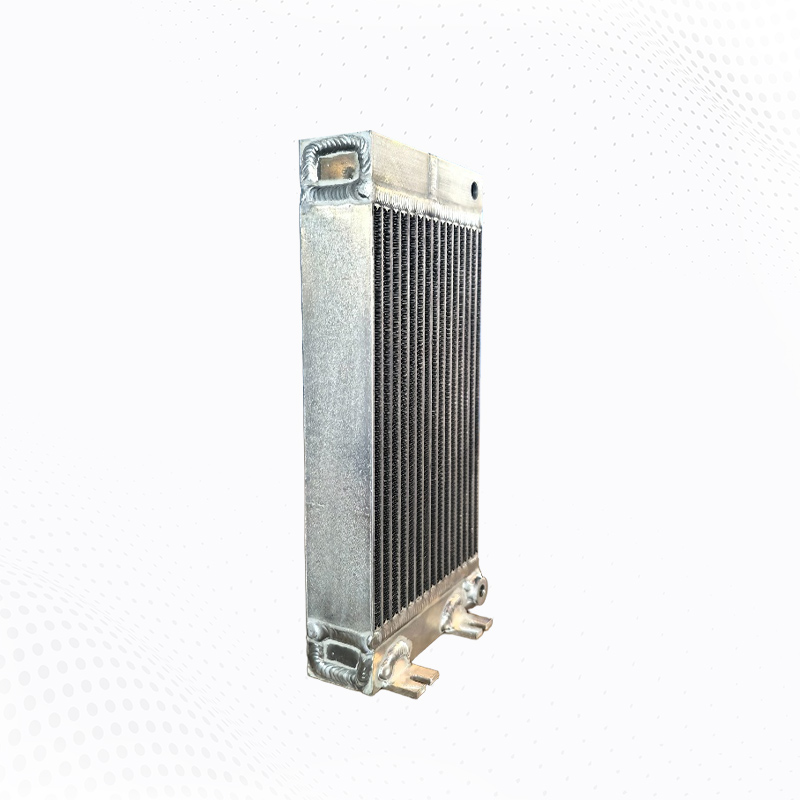

There are several types of hydraulic oil coolers, including air-cooled and water-cooled systems. Air-cooled hydraulic coolers rely on airflow to dissipate heat, while water-cooled hydraulic coolers use water to absorb and carry away heat. The choice of cooler depends on the application, environmental conditions, and the specific requirements of the hydraulic system.

A hydraulic cooler is usually made up of a heat exchanger, a fan (in air-cooled systems), and filters to remove contaminants from the fluid. The cooler helps maintain consistent fluid temperatures, preventing the hydraulic system from overheating and ensuring the system performs at its best.

Hydraulic System

A hydraulic system operates by using hydraulic fluid to transmit power from one part of a machine to another. The fluid is pressurized by a hydraulic pump, which allows it to flow through various components, such as cylinders, motors, and valves. As the fluid moves through the system, it absorbs heat from the components it interacts with, which can cause the temperature to rise significantly.

The efficiency of a hydraulic system depends on the fluid's ability to maintain its viscosity and flow characteristics. If the fluid becomes too hot, its viscosity decreases, leading to poor lubrication, increased friction, and potential damage to the system’s components. This is why maintaining the right temperature is essential for the smooth operation of the hydraulic system.

By using a hydraulic cooler, the temperature of the fluid can be kept within a specific range, ensuring that the fluid maintains its optimal viscosity, which helps maintain system pressure and power transmission. The cooler prevents the fluid from becoming too thick or too thin, ensuring the hydraulic system operates at peak efficiency and avoids costly breakdowns.

Hydraulic Oil Cooler

A hydraulic oil cooler is specifically designed to cool hydraulic fluid by removing the excess heat generated within the hydraulic system. It functions by using a heat exchanger that transfers the heat from the oil to a cooling medium, typically air or water. The fluid then returns to the system at a lower temperature, maintaining the optimal operating range for the hydraulic components.

In many industrial applications, the hydraulic oil cooler is crucial to the overall performance of the system. For instance, in heavy-duty machinery such as excavators, loaders, and presses, the hydraulic oil cooler helps to regulate the temperature of the fluid under extreme conditions, such as high-pressure operations or continuous use. In these environments, the oil cooler ensures that the hydraulic fluid does not overheat, which could lead to costly equipment damage and downtime.

The hydraulic oil cooler also plays a critical role in extending the lifespan of the hydraulic fluid. By preventing overheating and the breakdown of fluid, the cooler helps reduce the frequency of oil changes, saving on maintenance costs and improving the overall efficiency of the hydraulic system.